Have you ever gone to a concert and thought about how all those lights and wires were installed above the stage? Have you ever looked at a bridge and wondered about how it doesn’t fall?

Well, you can thank lifting engineers for those little miracles that often go unnoticed as we go about our daily lives.

-

Some Press and Journal online content is funded by outside parties. The revenue from this helps to sustain our independent news gathering. You will always know if you are reading paid-for material as it will be clearly labelled as “Partnership” on the site and on social media channels.

This can take two different forms.

“Presented by”

This means the content has been paid for and produced by the named advertiser.

“In partnership with”

This means the content has been paid for and approved by the named advertiser but written and edited by our own commercial content team.

Ross Moloney, chief executive officer of the Lifting Equipment Engineers Association (LEEA) explains:

Lifting is actually fighting gravity. How often does my life depend on successful fights with gravity? Actually, it’s all the time. Lifting is a service that’s provided to numerous markets on numerous supply chains. That can be oil and gas, automotive, heavy manufacturing. The list is almost endless.

So whether you’re a designer, seller, buyer, or someone who’s simply interested in all things lifting, consider going to LiftEx 2022.

The exhibition will be visited by over 1,500 industry professionals and nearly 100 exhibitors. Many of them will be showcasing (some even demonstrating) innovative and cutting-edge technologies that are available or just coming to the market.

Read on for a sneak peek at some of these LiftEx technologies.

LiftEx technologies you shouldn’t miss this year:

1. Hydra-Slide skidding system

This system provides a simple, safe, cost-effective and reliable method for moving, loading and unloading all types of heavy loads. All of its components are hand portable and its slim profile reduces space requirements and jacking time. It’s ideal for unique solutions when needing to move and lift boilers in industrial plant rooms, high voltage transformers, heavy presses, machinery and plant used in the power generation, defence and oil and gas process sectors right through to lighter manufacturing equipment in the beverage, distilling and food process sectors.

In the UK and Europe, Rapid Response Solutions (RRS) Group is the sole agent for Hydra-Slide.

2. Green Pin® Catch shackle

As pioneers in the field of safety, Green Pin® introduces the first plug-and-play solution to avoid dropping equipment and components from heights and prevent injuries or deaths. The Green Pin® Catch shackle prevents the accidental dropping of shackle bolts, nuts, cotter pins and complete shackles. It has been developed in cooperation with DROPS, the non-profit organization focusing on dropped objects prevention scheme.

Green Pin® is a brand of The Netherlands-based Royal Van Beest Group.

3. Virtual Reality (VR) Crane Simulation

Operating a crane is no easy feat. It takes specific skills and intensive training to control different types of machinery in various conditions.

But Industrial Training International (ITI) is making learning easier, and even fun, after developing a VR Crane and Equipment Training Suite with original equipment manufacturers. This technology helps students practice over a thousand scenarios in a safe environment. There are even portable desktop and motion-based platforms to meet any team’s needs.

4. Wireless load pins

A load pin is a customisable load monitoring transducer which is used for measuring the force or weight applied to a piece of equipment or system. It is used in a wide variety of applications in different industries. For example, it can be built into cranes to monitor the load or determine the line tension, hanging sheaves and integrated within OEM equipment, becoming part of a bigger system. Its primary purpose is to prevent overloading of the equipment they are installed in or used with, which prevents damage and promotes safety.

Now, Dynamic Load Monitoring (DLM) has designed a wireless load pin for installation in Capstan Winches (mechanical pulling devices) used to measure the load on cables being pulled into the turbines on offshore wind farms in the UK and Europe.

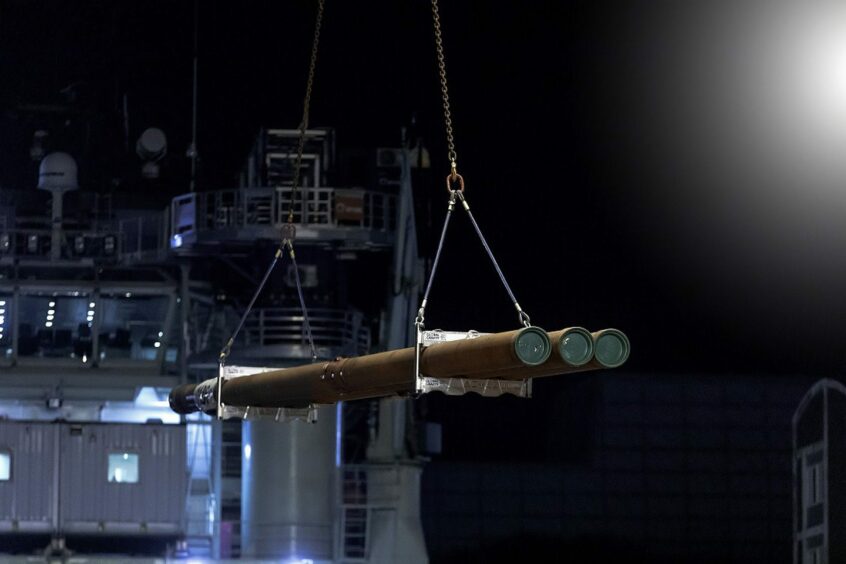

5. TubeLock Tubular transport and running system (TTRS)

This system consists of a series of aluminium frames that locks pipes securely in place, significantly reducing the risk of hand and foot injuries on offshore drilling rigs. It also allows more efficient stacking on supply boats and fewer trips, ultimately resulting in cost savings and reduced CO2 emissions.

Danish company, Global Gravity also designed the system to improve running efficiency. This means the pipes are marked and packed in running order onshore, eliminating the need to lay out and tally them. Offshore, they can be lifted directly from the supply vessel and onto the pipe deck, ready to run directly from the frames.

Find out more about what’s in store at this year’s LiftEx.