A plan to build a £4 million timber frame factory powered by renewable energy is expected to create 11 jobs near Ellon.

NorFrame will design and build the factory, which the company says will be the first of its kind in the UK, in Foveran.

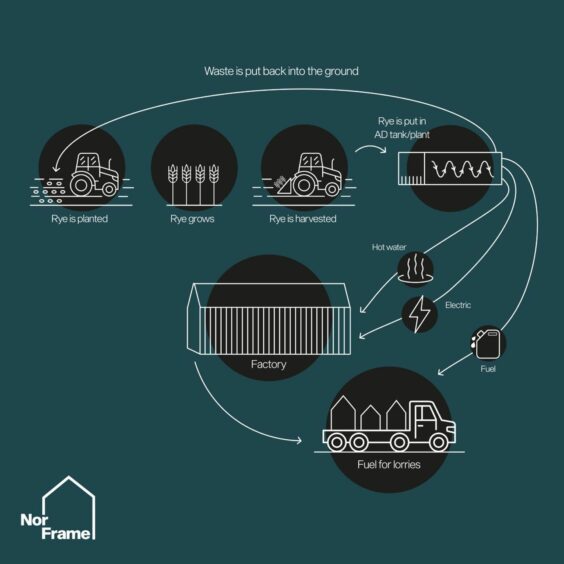

Power for the timber kit frame manufacturing will be generated from an on-site anaerobic digestion plant fuelled by silage from a neighbouring farm.

In doing so it will eliminate the need for fossil fuels to heat or power facility and its processes.

Eleven new jobs will be created and the factory will help safeguard a further 14, NorFrame said.

Spanning 31,000sq ft it’s expected to be completed by Spring next year and produce 20 timber kits per week which will be used to build homes, schools and commercial buildings.

Months of research and planning

NorFrame co-founder and director Gregor Davidson, who is also a director of Udney-based builder Cairnrowan Custom Homes, said: “Our goal was to solve a carbon footprint problem that would provide 100% assurance that a timber manufacturing process can be clean, green, and cost-effective.

“It was a eureka moment.”

Gregor Davidson, NorFrame co-founder and director

“The idea of combining the neighbouring anaerobic digestion plant and our own homegrown plant silage from a farm four miles away, with a two-zone heat capturing design came after months of testing and reworking our plans.

“It was a eureka moment.”

The neighbouring anaerobic digestor has been operational since 2014 and relies on feed in tariff (FiT) for viability.

Its current FiT agreement ends in 13 years’ time which meant it needed a lifeline to avoid being rendered redundant.

NorFrame’s factory will use up to 60% of the plant’s renewable electricity, assuring the plant’s future.

Explaining how the process will work Mr Davidson said: “It means that we take plant silage, ferment it for six months and then feed it into the anaerobic digestion plant which will power the factory.

“During that process, heat is created. Our idea is to capture that heat – which would have otherwise gone to waste – and redirect it to heat the entire factory and office space.

“And any waste from the digestion process is then used as fertiliser for next year’s crop. It is a fully organic, closed fuel cycle and we know it will make a significant contribution to Scotland’s net zero ambitions.”

Funding for build

NorFrame has been awarded £750,000 from the Scottish Enterprise low carbon manufacturing challenge fund. It’s the first grant to be given through the scheme.

In its submission, NorFrame detailed how the design will see many of its products achieve PassivHaus standards in thermal performance, air tightness and detailing, meaning its timber kits will meet rigorous energy efficient standards, therefore reducing the need for space heating in any building.

NorFrame co-founder Philip Edwards added: “Our clients have a variety of different thermal requirements depending on their own projects.

“Our new facility will allow us to cater for different solutions and showcase the products within our timber frame package.”

NorFrame plays ‘important role’

Earlier this year the Scottish Government announced new measures to slash carbon emissions of all new-build homes by a third (32%).

The new energy standards also apply to newly built non-domestic buildings and form plans to reduce emissions across Scotland’s building stock by more than two-thirds by 2030.

Enterprise Minister Ivan McKee said: “We are fully committed to reaching net zero by 2045 and developments such as NorFrame will play an important role to reach our goal.

“It’s great to see that new jobs will be created through this development. We are further supporting manufacturers’ innovation ambitions through the low carbon manufacturing challenge fund, whilst reducing emissions across Scotland as we tackle the global climate emergency.”

Conversation