A wealthy West Highland landowner is accelerating plans for “world-beating” biofuel technology.

Whisky residue from the distillery Donald Houston co-owns on his Ardnamurchan Estates will be used to test the process.

The west coast laird, whose estate covers about 25,000 acres of the most westerly extremity of the UK mainland, and boasts an abundance of wildlife, as well as holiday cottages, has invested more than £10 million in three businesses involved in the biofuel project.

One of these is Ardnamurchan Distillery, which Mr Houston co-owns with his neighour, Keith Falconer.

Another is Edinburgh-based Celtic Renewables, whose new production plant in Grangemouth will shortly start turning waste from whisky production into biofuels such as acetone, butanol and ethanol, as well as high-grade animal feed.

The facility – completed last autumn – is expected to process about 50,000 tonnes of residues every year from the whisky industry, turning it into low-carbon products displacing fossil fuel-based equivalents across a broad range of consumer markets.

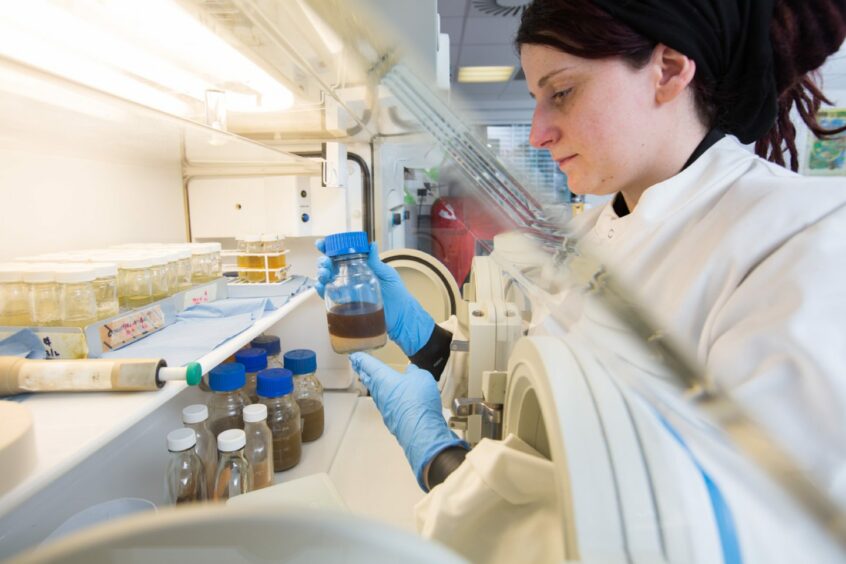

Celtic Renewables’ research and innovation is led by Aberdonian industrial biotechnologist Eve Bird.

The firm is targeting markets estimated to be worth more than £96 billon by 2025.

Also playing its part in getting biofuel production up and running at Grangemouth is Ardnamurchan-based Woodlands Renewables, which was formed to provide a sustainable, renewable and zero-waste solution for local commercial timber plantations.

The company produces wood fuel in the form of firewood for open fires and chips, pellets and briquettes for heating systems.

It supplies fuel to heat more than 20 homes, three hotels and a primary school, as well as to produce the high-pressure steam used by Ardnamurchan Distiller to heat its stills.

The Grangemouth bio refinery, believed to be the first of its kind in the world, is expected to produce about 220,000 gallons of sustainable biochemicals annually.

Celtic Renewables has attracted £43m of investment for the project and is already working on plans for large-scale refineries in other whisky-making locations around the world.

The time taken to start commissioning the renewable plant and produce a saleable output is very similar to that of having a saleable whisky ready on the market.”

Donald Houston, Ardnamurchan Estate.

Mr Houston said: ”Celtic Renewables needs a biproduct of whisky distilling called pot ale to assist in its testing process before starting full production of its biochemicals and biofuel.

“The pot ale is piped over the hill from the distillery to the neighbouring Woodland Renewables, a local business set up to repurpose the distillery’s by-products whilst adding value to the local economy.

“At the Woodland Renewables’ plant it is combined with draff – another distillery by-product – and turned into a nutritious animal feed used on the peninsula to feed local livestock.

“Woodland Renewables will transport part of their pot ale stock to Celtic Renewables.”

Ardnamurchan Distillery managing director Alex Bruce said: “Our energy all comes from local renewable sources – hydro and biomass – and our co-products, which are traditionally produced in all distilleries, are supplied to our neighbours, Woodland Renewables.

“We are incredibly excited they also now deliver additional value to Celtic Renewables for conversion into sustainable chemicals and biofuels.

“This combination is a fantastic example of collaborative, high value and sustainable long-term investment in the Scottish economy.”

Celtic Renewables’ founder and president Martin Tangney said Mr Houston’s “substantial” investment had been the catalyst for the company being spun out of research at Edinburgh Napier University in 2012.

Professor Tangney continued: “We have gone on to raise over £43m in multiple rounds and Donald has contributed consistently along the way.

“Donald took the risk on us when we had nothing more than a lab-based research project but with ambition for global domination.

A ‘stalwart’ investor

“He has been both a committed financial investor and a stalwart investor in the people and the concept behind the company ever since.

“Once in production we will have contracts for consistent supply of significant volumes of pot ale from the Scotch whisky industry.

“With the plant being commissioned, we needed an ad-hoc supply of pot ale on demand.

“Donald has stepped in to meet that need to get us through to the full production phase.”

Donald took the risk on us when we had nothing more than a lab-based research project but with ambition for global domination.”

Martin Tangney, founder and president, Celtic Renewables.

Mr Houston added: “The time taken to start commissioning the renewable plant and produce a saleable output is very similar to that of having a saleable whisky ready on the market.

“This long-term investment strategy, rather than the usual short-term commonly offered to start-ups, is crucial to the health of our economy.”