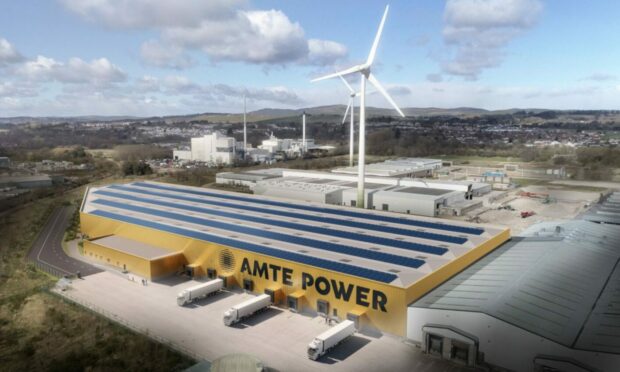

Battery-maker AMTE Power said its Thurso plant would remain “at the core of what we do” after it announced it will build its first “megafactory” at the former Michelin site in Dundee, creating 215 direct and 800 indirect jobs.

The site is expected to be operational and in production by the third quarter of 2025 based on current plans, although the Thurso-based company stressed its home town is still a key manufacturing facility for AMTE cells.

AMTE secured planning permission to extend its Thurso factory earlier this year.

Earlier today, the London-listed company told The Press & Journal local “know-how” was creating new opportunities in Caithness.

AMTE chief executive Kevin Brundish said: “Thurso is still really at the core of what we do. We have been making batteries at the plant since the late 1990s.

“It is the oldest established (battery) manufacturing plant in the UK. Generally speaking, it is absolutely at the heart of what we are doing.”

Thurso’s manufacturing capabilities are helping to accelerate development of next generation battery cells and scaled production.

This is alongside work to develop high-performance cells at the UK Battery Industrialisation Centre in Coventry.

Megafactory is ‘stepping stone’ to gigafactories of the future

The new Dundee plant will serve the UK renewable energy storage and electric vehicle markets.

AMTE said it would be a “stepping stone” to the construction of more gigafactories in the future, meeting huge demand for battery technology, particularly electric cars.

Michelin exited the Dundee site last year, with the final workers exiting to the sound of bagpipes and applause marking the end of almost 50 years of tyre production and generations of jobs at the plant.

The transformation of Michelin’s Dundee tyre factory into a Michelin Scotland Innovation Parc for high-tech innovation has been hailed as a worldwide “benchmark” for communities.

AMTE’s Dundee plans aim to deliver capacity for more than 25,000 batteries per day, or eight million a year, regenerating revenue of more than £200 million annually at full production.

Total required investment in the megafactory is estimated to be between £160m-190m.

AMTE has received an indicative offer letter from Scottish Enterprise regarding a potential package of funding and business support.

The megafactory is expected to be funded by a combination of grant finance, as well as traditional and government assisted debt and equity.

AMTE has inked a binding letter of intent with Michelin Scotland Innovation Parc for the site, ahead of a formal lease agreement to be signed in the fourth quarter of 2022.

Transferable knowledge

Concerning the jobs required in Dundee, Mr Brundish stressed the “highly skilled” nature of the work involved and cited the availability of staff in the area with transferable knowledge, following closure of the Michelin site.

He added: “We are looking to get the facility up and running as fast as we can. We do see this very much as a stage on our journey to meet large demand.

“The megafactory will be a platform from which AMTE can harness our in-house capabilities to build manufacturing plants to meet the huge demand for battery cells.

“Battery cells are fundamental to enabling the UK’s energy transition and, with this investment, we will play a key role in electrifying the vehicles, homes and industries of the future.

“The site at Dundee is the ideal location for a megafactory; it has local industry knowledge and is close to our current and future market in energy storage.”

Support from UK government

The megafactory has received support from the UK Government’s Automotive Transformation Fundwhich , will help to finance detailed planning.

AMTE expects the project to receive further “significant” funding offers on “favourable” terms.

AMTE noted “huge” demand for battery cells, with some estimates putting installations of home energy storage batteries rising from six gigawatt hours (GWh) in 2019 to 155GWh annually by 2030.

Currently only 5% of the energy used to heat UK homes comes from low-carbon sources and massive growth is expected as part of the transition to net-zero in the next 15 to 20 years.

In the electric vehicle market, the UK Government has set a 2030 deadline to end the sale of petrol and diesel cars.

In addition, legislation is coming into force in two years’ time which will stipulate cars made in the EU or UK need to contain up to 50% of locally sourced materials in order to avoid tariffs.

Conversation