Virtual reality (VR) technology used in subsea energy and other sectors is being developed to improve the health and safety of divers on north fish farms.

In a first for the aquaculture sector, the system will use underwater 3D scanning.

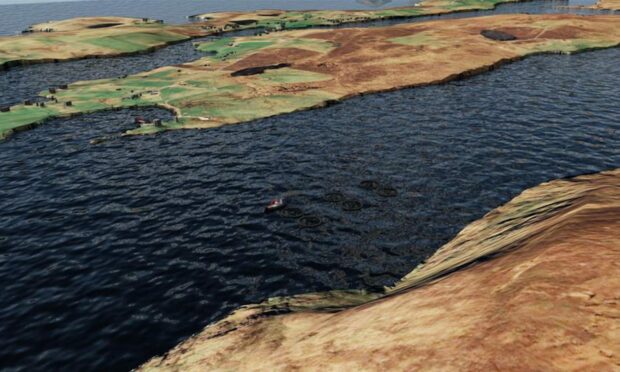

An initial trial will see images captured by remotely-operated vehicles (ROVs) used to create a virtual replica of a fish farm, or ‘”digital twin”, supporting divers to plan activities ahead of entering the water.

Virtual fish farms

Led by researchers at the National Manufacturing Institute Scotland (NMIS), run by Strathclyde University, the project was recently awarded funding of around £50,000 from the UK Seafood Innovation Fund.

Further support has come from the Sustainable Aquaculture Innovation Centre (SAIC) in Stirling.

It is hoped the technology will, eventually, allow the industry to replace paper-based planning with mobile phones, tablets or even VR headsets to gain a better understanding of fish farm locations.

Digital data will help farms assess the difficulty of dives, what actions are required in terms of maintenance and cleaning, and whether any additional equipment is needed underwater.

SAIC innovation and engagement director Sarah Riddle said: “This is a great example of how the aquaculture sector can work together with experts in subsea technology, manufacturing and other industries to learn from best practice and accelerate digital transformation.

“Designed specifically for seafood producers, the new tool could support training, maintenance, inspections and even environmental monitoring, helping to future-proof the sector as it continues to grow.”

This is a great example of how the aquaculture sector can work together with experts in subsea technology.”

Sarah Riddle, innovation and engagement director, SAIC.

Awais Munawar, visualisation theme lead, digital factory, NMIS, said: “3D scanning and VR technology is already used in many industries such as aerospace and energy, and there could be a significant opportunity for aquaculture to follow.

“Of course, there are also challenges to overcome, which is the purpose of this feasibility study.

“For instance, fish farms are not fixed structures in the way that many oil platforms are, and the environment can be quite different depending on the location and depth of the water.”

Mr Munawar added: “We are also looking to test a small 5G network to improve communications as part of diving activity in remote locations.

“This could be used to update the information captured by the remotely-operated vehicles in real-time, as well as being used to alert any nearby vessels to the fact divers are in the water.

“In the future, the system could have the potential to become part of a full digital twin, with additional data and images already captured by sites integrated into the platform to give a full picture of the situation under the water.”

North-east firms involved

NMIS is working with Aberdeen firm Ocean Kinetics, a provider of diving services to a range of sectors including aquaculture, energy and renewables, and Newburgh, Aberdeenshire-based Viewport3, specialists in subsea 3D scanning, to create a test platform on a Scottish Sea Farms site in Shetland.

Diving is considered one of the most complex and dangerous roles in aquaculture still undertaken manually, but the new digital planning tool could boost health and safety in a range of ways.

With better access to information ahead of a dive, it could reduce the time needed in the water, support a better understanding of new or unfamiliar sites, and identify additional training or support needs.

It may also improve the efficiency of maintenance programmes, with the images captured by ROVs identifying issues such as the presence of marine growth ahead of divers going underwater. More streamlined dive schedules could also reduce interaction with fish.

Conversation