A sawmill worker in Lochaber who has been keeping things sharp for more than 50 years, says it is his love of motorbikes and fishing that keeps him going.

Joking that he “still has all his fingers”, Dick Power, 72, wouldn’t say he loved the work – but his colleagues hold him in high esteem for his meticulous attention to detail.

He is the longest-serving worker at the BSW Timber sawmill in Fort William.

Best paying job in sawmill

When Mr Power started in the sawmill in 1974 he came across the country from Speyside because his father had moved to the original site of the sawmill at Corpach.

He had already been in the trade for seven years at that time. He had experience of working on a portable mill – where the saw doctor went to the forest.

He came to Corpach when the sawmill was on the other side of the road to where the massive woodyard sits now on the shorefront at Corpach.

Mr Power said: “I got a chance to come to be a saw doctor or an apprentice mechanic.

“I did ask what job was the best paid and I was told it was as a saw doctor so I took up the job.”

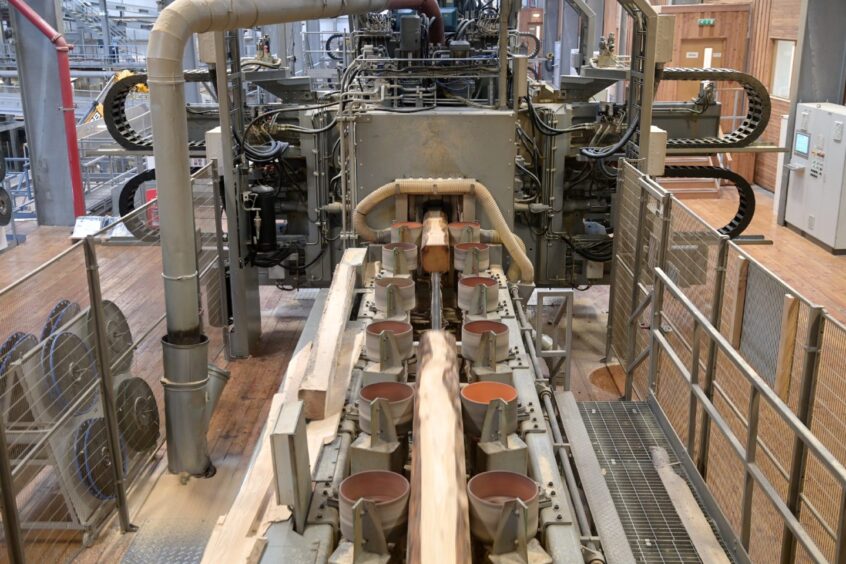

A saw doctor is the person in the sawmill who makes sure the cutting machines – which are worth millions of pounds – are working correctly and that each saw is cutting well.

There are hundreds of saws within the machinery – each programmed to make individual cuts of wood.

Taking logs from nearby forests – as many as 50,000 a week – and turning the wood into components for other industries such as construction.

End to end the lengths of wood made from logs at Corpach would be able to stretch the length of the UK every week.

Waste product is also used in papermills, no longer in Corpach, and in chipboard.

Over the years, Mr Power has seen some gruesome accidents, but has managed to keep relatively accident-free himself “touch wood”.

He said: “The top of one of my fingers doesn’t work well, and I have seen people lose hands and fingers. But, touch wood, apart from cuts and scrapes I have never had a problem.”

Mr Power is one of a team of eight workers who are on shift every day.

His supervisor Iain Johnston – who was once Mr Power’s apprentice – says it is a “hard but satisfying” job.

Mr Johnston said: “We even process wood here that goes to China.

“It is an important job and involves using a lot of computers these days. Health and safety will have improved over the years.

“But there are still some jobs that are difficult.”

One of those is replacing band saws in one part of the factory.

Mr Johnston said: “There was a time that we were using a lamp, a hammer and a straight edge to make sure we had the blade fixed correctly.

100% safer than what we used to do

“There is a lot more computerised work to it now. But we are still doing the same job in making sure the blades are sharpened for use in the cutting and shaping of wood.

“What we do is 100% safer than what we used to do.”

Mr Power – who owns a large number of motorbikes including a Norton – and who loves to go fishing has no intention of giving up work anytime soon.

Declining to be photographed, Mr Power laughed: “This job keeps me fishing and to pay for my motorbikes. Otherwise, I am a very private person. ”

Have you signed up for our Oban, Fort William and Hebrides newsletter?

Every week our Oban-based reporter Louise Glen curates the best news in the area.

Sign up here for local news straight to your inbox.

Conversation