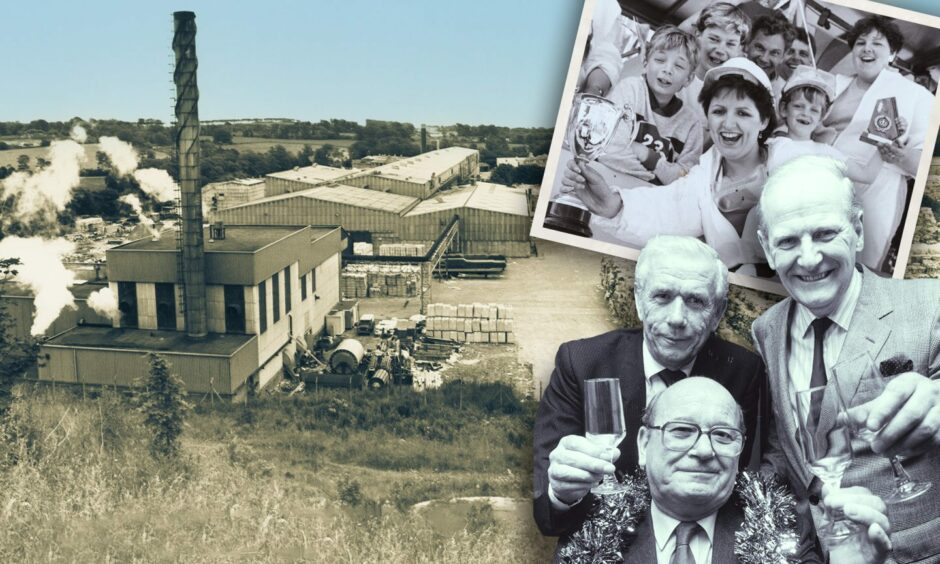

Many generations of Aberdonians spent their entire working life at Mugiemoss paper mill over its 200-year existence.

It wasn’t just about work.

The loyalty and long service was about the family feel of the place, and there were many sore hearts when the mill finally closed in 2005.

Here we celebrate its history and people. Were you there?

Please post your memories in the comments below!

‘Aye tae the fore!’ was the battle cry of the founders of Mugiemoss Mill.

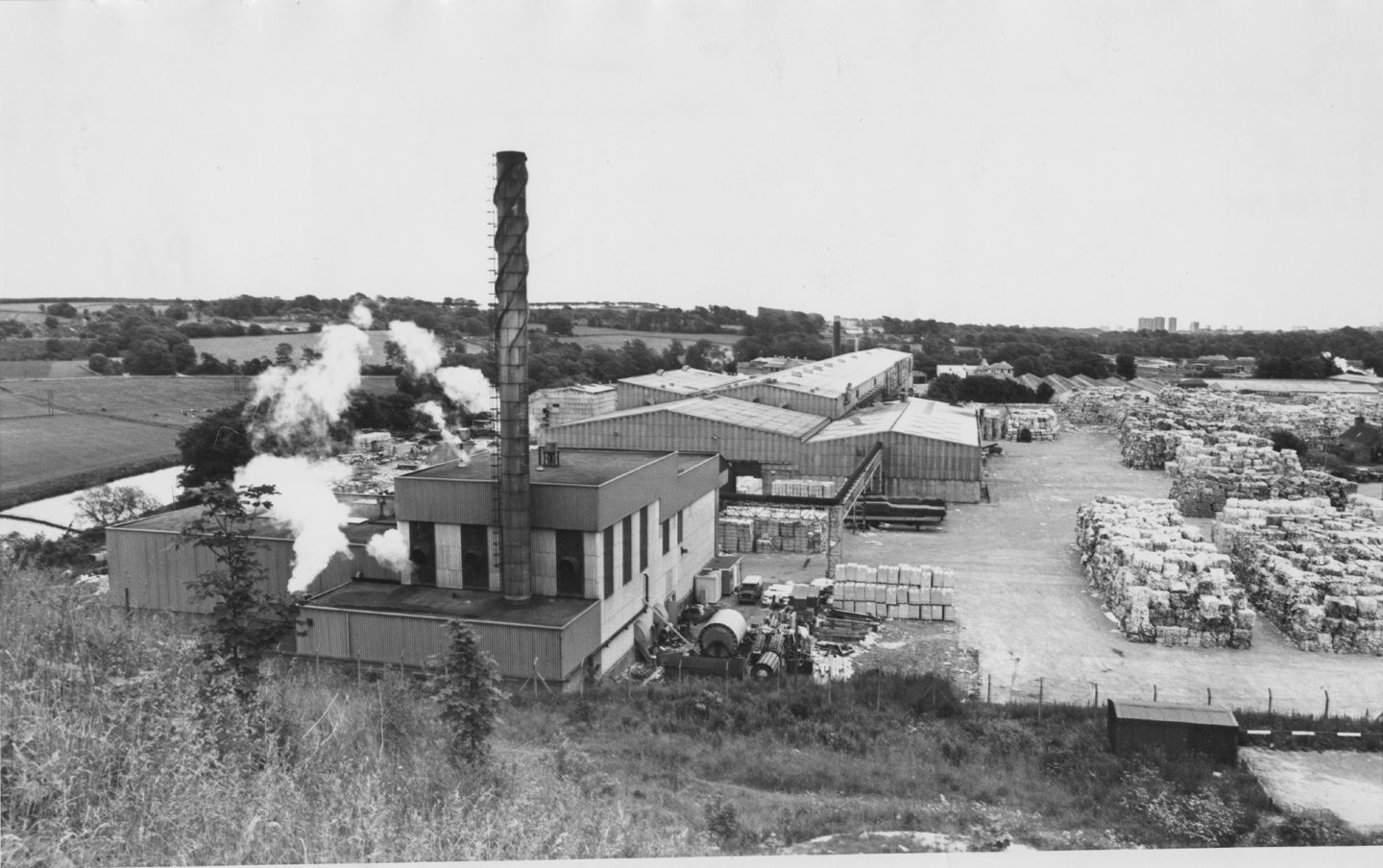

During the two centuries that the paper mill presided over Bucksburn, that slogan was needed again and again as the company adapted to changing times.

Towards the end of the 18th century, Tarland millwright Charles Davidson and his friend Charles Smith began making paper at Stoneywood.

Business boomed and they took over another site at Mugiemoss.

Davidson family took control

By 1776 the entrepreneurs decided the market was big enough for both of them and, legend has it, on the toss of a coin, Davidson took sole charge of Mugiemoss.

The firm became C. Davidson and Sons when William Jnr and George joined in 1830.

George left 10 years later while William brought his brood of five sons into the factory.

Around 1857 Davidsons’ made the breakthrough which gave it worldwide fame – the invention of a machine which made bags mechanically rather than by hand.

Thirty years later they were the largest makers of machine-made bags in the world, making more than two million bags a week.

In 1875 the firm was converted to a limited company.

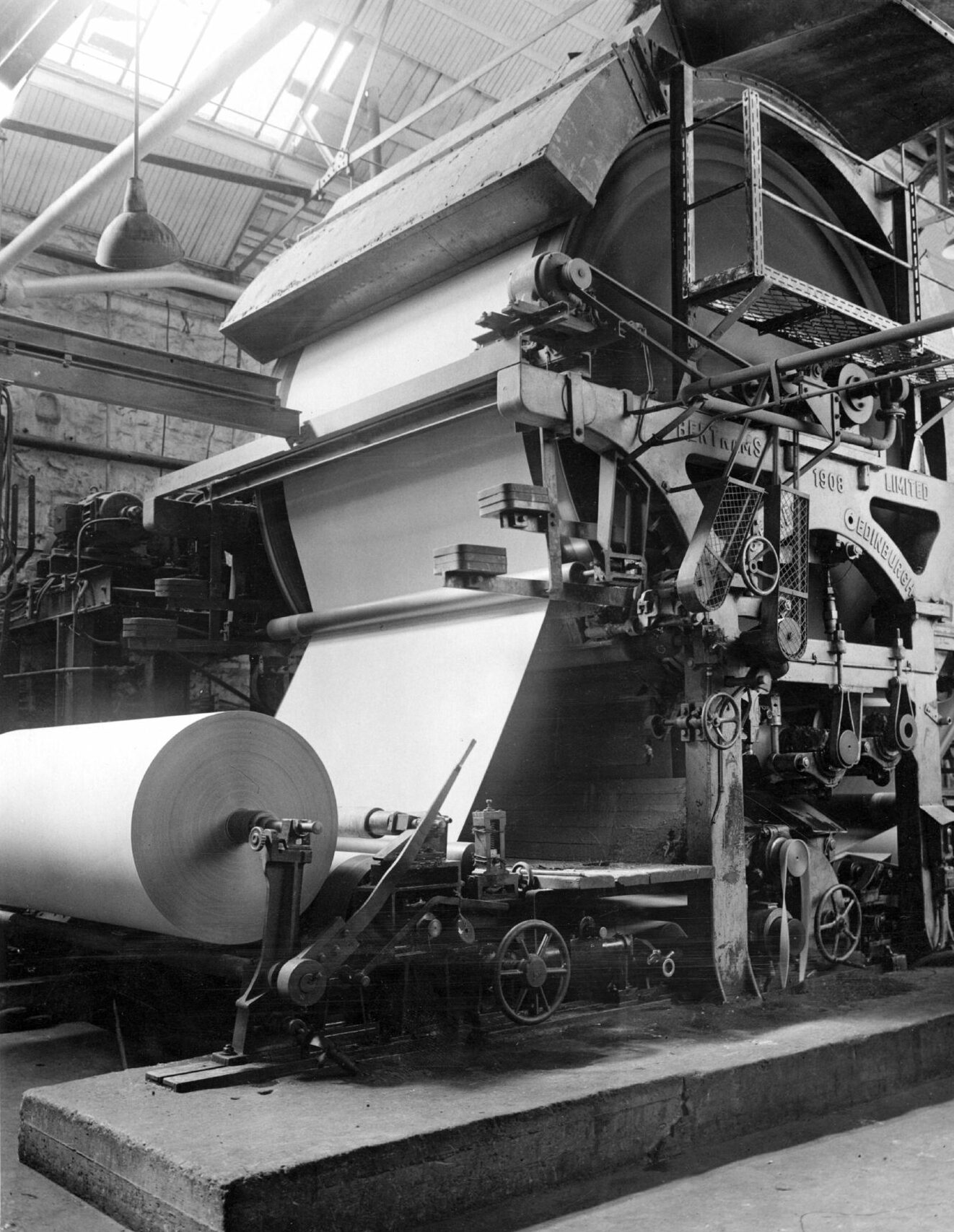

Two paper machines were producing more than 100 tons per week and in 1908, keeping abreast of latest developments, the Davidsons’ introduced a third machine making thinner, stronger paper.

The company took out patents on new products, one of which turned out to be a long-time winner.

Cedar Felt was grey paper lined with a thin layer of a mixture of cedar dust and wood pulp.

The genius was that moths hated the smell of cedar, and the felt prevented dust from coming through the floorboards when used under carpets.

Like most other industries, World War 1 drained Mugiemoss of its young and the mill faced a tough battle for survival.

The 1921 slump was even worse as the price of paper plummeted in just a few weeks and more than 100 mills in other parts of Britain went to the wall.

But Mugiemoss managed to limp on, often closing down for periods or leaving parts of the site uninsured to save on premiums.

A change in production

The next major development came in 1930 when they moved into making paperboard which, along with making blackouts, helped them weather World War 2.

Dundee-founded Abertay Paper Sacks moved into Mugiemoss in 1953 while the year before Davidsons’ became part of the giant BPB Industries – a group of companies then the biggest producers of packaging and building board in the UK.

Investment, diversification and keeping up with new technology have been paramount in the development of the Mugiemoss site ever since.

A 1930s invention Ibeco Paper, was a strong, waterproof paper which proved extremely successful for the next 40 years.

It was used as an underlay for the concrete on the original East Lancashire road and the Wembley Ice Rink, before being widely used as black out material during the Second World War.

The Davidson family remained at the helm for 157 years until 1953 when British Plasterboard took out a 45% share in the company.

It was a time of expansion and increased profits, seeing more than 1,000 employees working three shifts at the mill to make bags, cartons and paper sacks.

The demand for plasterboard liner fuelled growth in the 1960s, but the 1970s saw plastic alternatives displacing Ibeco paper.

The machine finally closed in March 1981, bringing an end to the manufacturing of paper at Mugiemoss after 185 years.

Over to plasterboard manufacture for a few boom years in the 1980s.

By the 1990s, the writing was on the wall and Mugiemoss Mill closed in 2005.

End of an era when Mugiemoss Mill closed

Mill historian Ian Booth wrote: “In the end, we were somewhat the victims of our own success.

“Over the last 20 to 30 years we persevered with two paperboard machines, developed almost to the ultimate within their design capabilities.

“There was nowhere else to go except to a new much wider machine, but the capital required for that was never going to be – not from BPB and not at Mugiemoss.

“Ultimately the width of our machines that beat us, not the technology, and certainly not the will to succeed.”

It was an emotional ending of an era on June 30 2005.

Mr Booth said: “It brought to an end a remarkable story of courage growth, progress, recognition, pride, and finally sorrow.

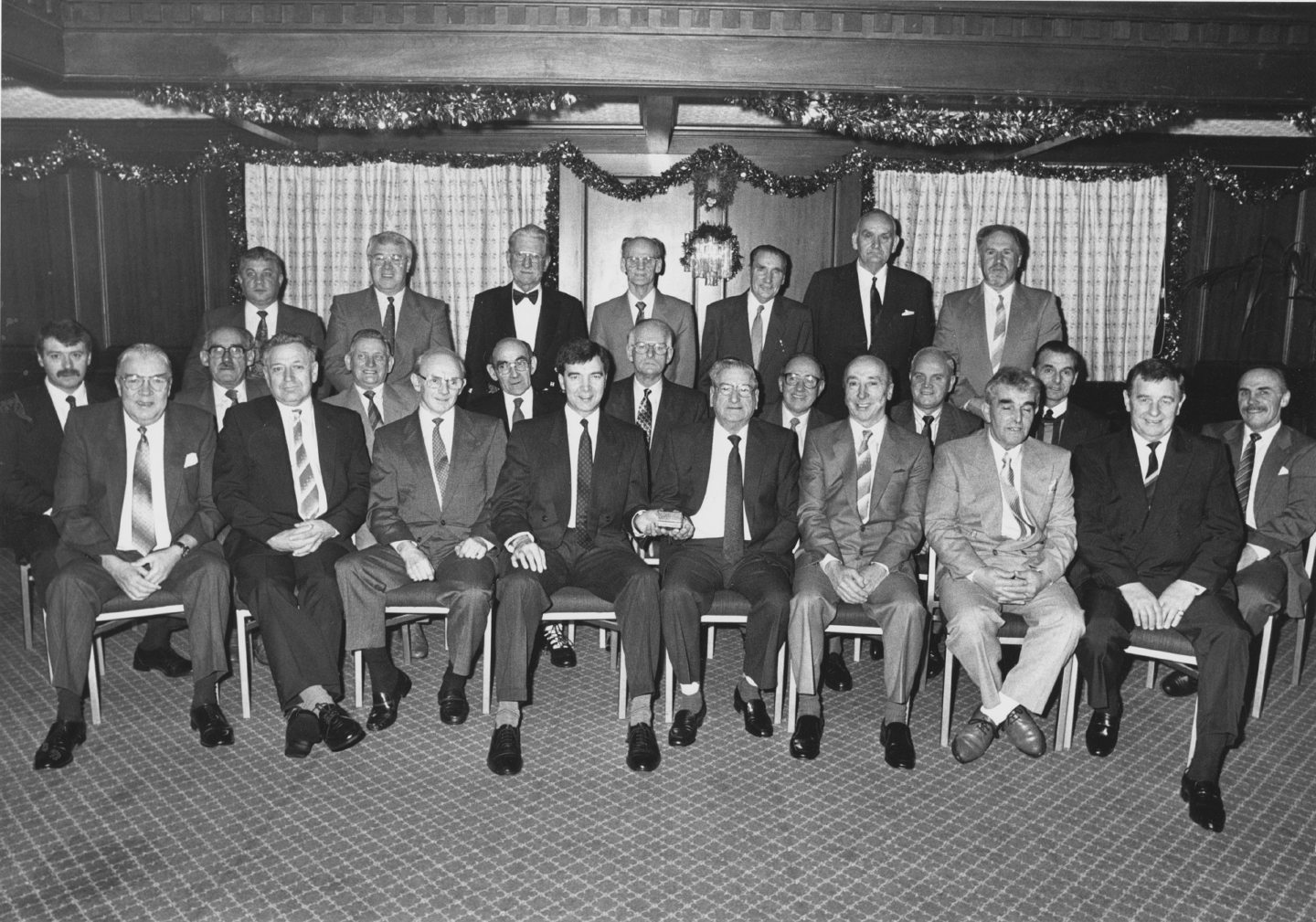

“There were many people who have spent most of their working life with just one company, Mugiemoss Mill.

“The list of long service personnel is long, testament to the lure and variety of the place and the family feel the mill held for generations.”

More like this:

Conversation